DIN338 to'liq tuproqli HSS M2 Twist matkap uchlari

Xususiyatlari

DIN338 to'liq tuproqli HSS M2 burama burg'ulash uchi bir nechta ajoyib xususiyatlarga ega, jumladan:

Yuqori tezlikli po'lat (HSS) M2 Material: HSS M2 materialidan foydalanish yuqori qattiqlik, aşınma qarshilik va issiqlikka chidamlilikni ta'minlaydi, bu matkap uchlarini zanglamaydigan po'lat, qotishma po'lat va metall bo'lmagan materiallarni o'z ichiga olgan turli xil materiallarni burg'ulash uchun mos qiladi. qora metall.

TO'LIQ ZAMONLANGAN FLUTALAR VA KESISH CHEKLAR: Burg'ulash uchi o'tkir va izchil oluklar va chiqib ketish qirralarini ta'minlash uchun nozik silliqlash bo'lib, chiplarni evakuatsiya qilishni yaxshilaydi, ishqalanishni kamaytiradi va burg'ulash aniqligini oshiradi.

135 graduslik bo'linish nuqtasi: Matkap uchi 135 graduslik bo'linish nuqtasi dizaynini qabul qiladi, bu uchuvchi teshiklarga bo'lgan ehtiyojni kamaytirishga yordam beradi, markazlashtirish va o'z-o'zini markazlashtirish imkoniyatlarini oshiradi va burg'ulash samaradorligini oshiradi.

YALTIRILGAN FINISH: Matkap uchidagi yorqin qoplama korroziyaga qarshi turadi, chip oqimini yaxshilaydi va ish paytida yaxshilangan ko'rinishni ta'minlaydi, ishlash va xizmat muddatini yaxshilashga yordam beradi.

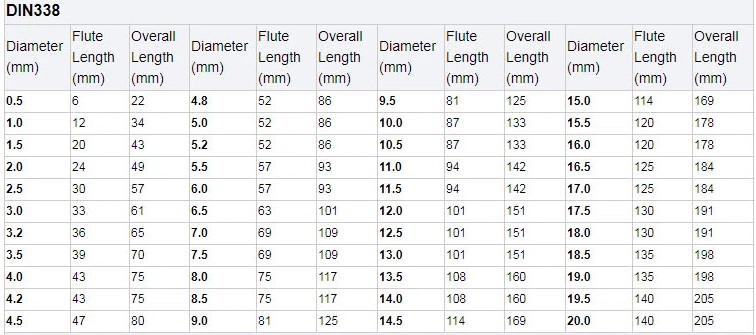

DIN338 mos: Matkaplar DIN338 standartlariga mos keladi, bu izchil o'lchamlarni, yuqori sifatli ishlab chiqarishni ta'minlaydi va aniqlik va ishonchlilik uchun sanoat standartlariga javob beradi.

Ko'p qirrali ilovalar: Bu burama matkap uchlari turli xil materiallarda umumiy burg'ulash vazifalari uchun mos keladi, bu ularni turli xil burg'ulash ilovalari uchun ko'p qirrali va amaliy qiladi.

Asbobning uzoq umr ko'rish muddati: Yuqori sifatli HSS M2 materiallari, nozik silliqlash va bardoshli dizayn kombinatsiyasi asbobning ishlash muddatini uzaytiradi va almashtirish va texnik xizmat ko'rsatish chastotasini kamaytiradi.

Bu xususiyatlar birgalikda DIN338 to'liq tuproqli HSS M2 burama matkap uchini professional va sanoat burg'ulash ilovalari uchun ishonchli, yuqori samarali vositaga aylantiradi.

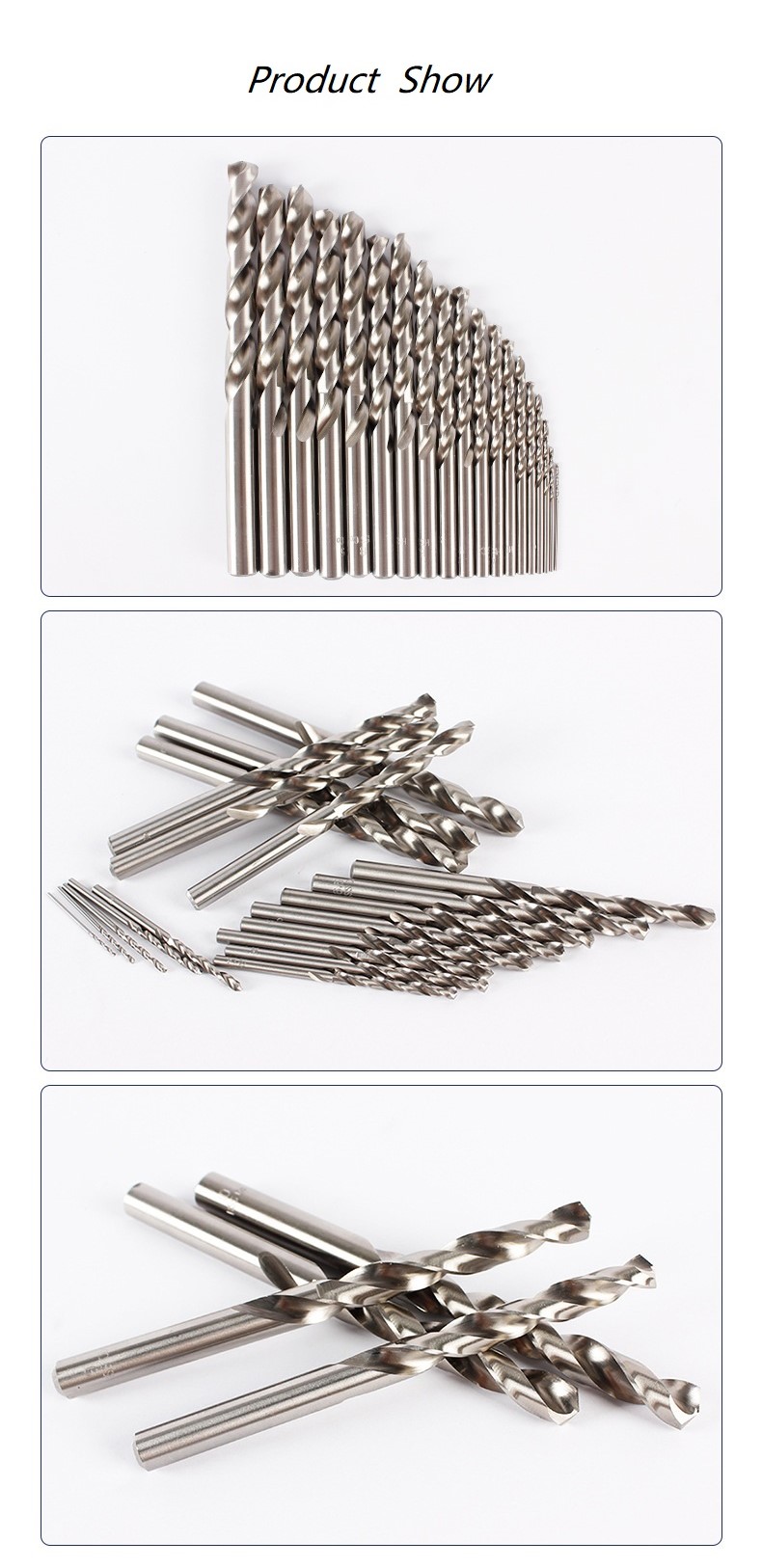

PRODUCT namoyishi

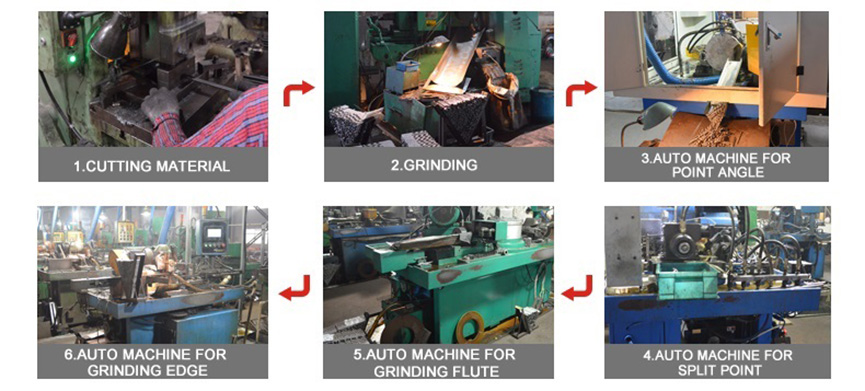

JARAYON OQIMI

Afzalliklar

DIN338 to'liq tuproqli HSS M2 burama burg'ulash uchlari turli afzalliklarga ega, jumladan:

Yuqori chidamlilik: HSS M2 materiali, ayniqsa, zanglamaydigan po'lat, qotishma po'lat va rangli metallar kabi qattiq materiallarni burg'ulashda uzoq muddatli chidamlilik uchun yuqori qattiqlik va aşınma qarshiligini ta'minlaydi.

Aniqlik va aniqlik: To'liq maydalangan naylar va chiqib ketish qirralari aniq va izchil burg'ulash ishlashini ta'minlaydi, toza, aniq teshiklarni hosil qiladi.

Chiplarni samarali evakuatsiya qilish: Nozik tuproqli oluklar va kesish qirralari chiplarni samarali evakuatsiya qilishni osonlashtiradi, tiqilib qolishni minimallashtiradi va burg'ulash samaradorligini oshiradi.

Burg'ilash tezligini oshirish: 135 graduslik bo'linish nuqtasi dizayni oldindan burg'ulashga bo'lgan ehtiyojni kamaytiradi, bu esa tezroq burg'ulash va samaradorlikni oshirish imkonini beradi.

Issiqlik va ishqalanishni pasaytiradi: Yuqori tezlikli po'latdan yasalgan material va nozik silliqlash burg'ulash paytida issiqlik hosil bo'lishini va ishqalanishni kamaytirishga yordam beradi, bu esa silliqroq ishlash va asbobning ishlash muddatini uzaytiradi.

Korroziyaga chidamlilik: matkap uchidagi yorqin sirt korroziyaga chidamli bo'lib, matkap uchining ishlash muddatini uzaytiradi va uning kesish ish faoliyatini saqlaydi. Ko'p qirralilik: Bu matkap uchlari turli xil burg'ulash ilovalari uchun mos keladi, bu ularni turli materiallar va sanoatda foydalanish uchun ko'p qirrali va amaliy qiladi.

Ushbu afzalliklarni taqdim etish orqali DIN338 to'liq tuproqli HSS M2 burama matkap uchi burg'ulash operatsiyalarida ishonchlilik, samaradorlik va uzoq umr ko'rishni ta'minlaydi.

| DIN338 HSS burama burg'ulash uchlari | ||||||||

| Diametri (mm) | Fleyta uzunligi (mm) | Umumiy uzunlik (mm) | Diametri (mm) | Fleyta uzunligi (mm) | Umumiy uzunlik (mm) | Diametri (mm) | Fleyta uzunligi (mm) | Umumiy uzunlik (mm) |

| 0,2 | 2.5 | 19.0 | 5.6 | 57,0 | 93,0 | 11.0 | 94,0 | 142,0 |

| 0.3 | 3.0 | 19.0 | 5.7 | 57,0 | 93,0 | 11.1 | 94,0 | 142,0 |

| 0.4 | 5.0 | 20.0 | 5.8 | 57,0 | 93,0 | 11.2 | 94,0 | 142,0 |

| 0,5 | 6.0 | 22.0 | 5.9 | 57,0 | 93,0 | 11.3 | 94,0 | 142,0 |

| 0,6 | 7.0 | 24.0 | 6.0 | 57,0 | 93,0 | 11.4 | 94,0 | 142,0 |

| 0,7 | 9.0 | 28.0 | 6.1 | 63,0 | 101,0 | 11.5 | 94,0 | 142,0 |

| 0,8 | 10.0 | 30.0 | 6.2 | 63,0 | 101,0 | 11.6 | 94,0 | 142,0 |

| 0,9 | 11.0 | 32.0 | 6.3 | 63,0 | 101,0 | 11.7 | 94,0 | 142,0 |

| 1.0 | 12.0 | 34.0 | 6.4 | 63,0 | 101,0 | 11.8 | 94,0 | 142,0 |

| 1.1 | 14.0 | 36,0 | 6.5 | 63,0 | 101,0 | 11.9 | 101,0 | 151,0 |

| 1.2 | 16.0 | 38,0 | 6.6 | 63,0 | 101,0 | 12.0 | 101,0 | 151,0 |

| 1.3 | 16.0 | 38,0 | 6.7 | 63,0 | 101,0 | 12.1 | 101,0 | 151,0 |

| 1.4 | 18.0 | 40,0 | 6.8 | 69,0 | 109,0 | 12.2 | 101,0 | 151,0 |

| 1.5 | 18.0 | 40,0 | 6.9 | 69,0 | 109,0 | 12.3 | 101,0 | 151,0 |

| 1.6 | 20.0 | 43,0 | 7.0 | 69,0 | 109,0 | 12.4 | 101,0 | 151,0 |

| 1.7 | 20.0 | 43,0 | 7.1 | 69,0 | 109,0 | 12.5 | 101,0 | 151,0 |

| 1.8 | 22.0 | 46,0 | 7.2 | 69,0 | 109,0 | 12.6 | 101,0 | 151,0 |

| 1.9 | 22.0 | 46,0 | 7.3 | 69,0 | 109,0 | 12.7 | 101,0 | 151,0 |

| 2.0 | 24.0 | 49,0 | 7.4 | 69,0 | 109,0 | 12.8 | 101,0 | 151,0 |

| 2.1 | 24.0 | 49,0 | 7.5 | 69,0 | 109,0 | 12.9 | 101,0 | 151,0 |

| 2.2 | 27.0 | 53,0 | 7.6 | 75,0 | 117,0 | 13.0 | 101,0 | 151,0 |

| 2.3 | 27.0 | 53,0 | 7.7 | 75,0 | 117,0 | 13.1 | 101,0 | 151,0 |

| 2.4 | 30.0 | 57,0 | 7.8 | 75,0 | 117,0 | 13.2 | 101,0 | 151,0 |

| 2.5 | 30.0 | 57,0 | 7.9 | 75,0 | 117,0 | 13.3 | 108.0 | 160,0 |

| 2.6 | 30.0 | 57,0 | 8.0 | 75,0 | 117,0 | 13.4 | 108.0 | 160,0 |

| 2.7 | 33.0 | 61,0 | 8.1 | 75,0 | 117,0 | 13.5 | 108.0 | 160,0 |

| 2.8 | 33.0 | 61,0 | 8.2 | 75,0 | 117,0 | 13.6 | 108.0 | 160,0 |

| 2.9 | 33.0 | 61,0 | 8.3 | 75,0 | 117,0 | 13.7 | 108.0 | 160,0 |

| 3.0 | 33.0 | 61,0 | 8.4 | 75,0 | 117,0 | 13.8 | 108.0 | 160,0 |

| 3.1 | 36,0 | 65,0 | 8.5 | 75,0 | 117,0 | 13.9 | 108.0 | 160,0 |

| 3.2 | 36,0 | 65,0 | 8.6 | 81,0 | 125,0 | 14.0 | 108.0 | 160,0 |

| 3.3 | 36,0 | 65,0 | 8.7 | 81,0 | 125,0 | 14.3 | 114,0 | 169,0 |

| 3.4 | 39,0 | 70,0 | 8.8 | 81,0 | 125,0 | 14.5 | 114,0 | 169,0 |

| 3.5 | 39,0 | 70,0 | 8.9 | 81,0 | 125,0 | 14.8 | 114,0 | 169,0 |

| 3.6 | 39,0 | 70,0 | 9.0 | 81,0 | 125,0 | 15.0 | 114,0 | 169,0 |

| 3.7 | 39,0 | 70,0 | 9.1 | 81,0 | 125,0 | 15.3 | 120,0 | 178,0 |

| 3.8 | 43,0 | 75,0 | 9.2 | 81,0 | 125,0 | 15.5 | 120,0 | 178,0 |

| 3.9 | 43,0 | 75,0 | 9.3 | 81,0 | 125,0 | 15.8 | 120,0 | 178,0 |

| 4.0 | 43,0 | 75,0 | 9.4 | 81,0 | 125,0 | 16.0 | 120,0 | 178,0 |

| 4.1 | 43,0 | 75,0 | 9.5 | 81,0 | 125,0 | 16.3 | 125,0 | 184,0 |

| 4.2 | 43,0 | 75,0 | 9.6 | 87,0 | 133,0 | 16.5 | 125,0 | 184,0 |

| 4.3 | 47,0 | 80,0 | 9.7 | 87,0 | 133,0 | 16.8 | 125,0 | 184,0 |

| 4.4 | 47,0 | 80,0 | 9.8 | 87,0 | 133,0 | 17.0 | 125,0 | 184,0 |

| 4.5 | 47,0 | 80,0 | 9.9 | 87,0 | 133,0 | 17.3 | 130,0 | 191,0 |

| 4.6 | 47,0 | 80,0 | 10.0 | 87,0 | 133,0 | 17.5 | 130,0 | 191,0 |

| 4.7 | 47,0 | 80,0 | 10.1 | 87,0 | 133,0 | 17.8 | 130,0 | 191,0 |

| 4.8 | 52,0 | 86,0 | 10.2 | 87,0 | 133,0 | 18.0 | 130,0 | 191,0 |

| 4.9 | 52,0 | 86,0 | 10.3 | 87,0 | 133,0 | 18.5 | 135,0 | 198.0 |

| 5.0 | 52,0 | 86,0 | 10.4 | 87,0 | 133,0 | 18.8 | 135,0 | 198.0 |

| 5.1 | 52,0 | 86,0 | 10.5 | 87,0 | 133,0 | 19.0 | 135,0 | 198.0 |

| 5.2 | 52,0 | 86,0 | 10.6 | 87,0 | 133,0 | 19.3 | 140,0 | 205.0 |

| 5.3 | 52,0 | 86,0 | 10.7 | 94,0 | 142,0 | 19.5 | 140,0 | 205.0 |

| 5.4 | 57,0 | 93,0 | 10.8 | 94,0 | 142,0 | 19.8 | 140,0 | 205.0 |

| 5.5 | 57,0 | 93,0 | 10.9 | 94,0 | 142,0 | 20.0 | 140,0 | 205.0 |